FOOD GRADE SUCTION &DISCHARGE HOSE

FDA GRADE SUCTION & DISCHARGE HOSE is suitable for milk, fruit juices, soft drinks, beer, wine, pharmaceuticals, cosmetics and other non-oily food products. Its tube is made of a high-temperature synthetic rubber compound that meets 3-A, United States Department of Agriculture (USDA), and Food and Drug Administration (FDA) standards for food handling. It has a smooth bore that encourages maximum flow rates and inhibits bacterial growth. The cover is made of corrugated gray nitrile for flexibility and resistance to chemicals, heat, and aging. It can be used with a variety of coupling options (not included). This Food Discharge Hose assembly is suitable for a wide range of applications in the food and beverage industries.

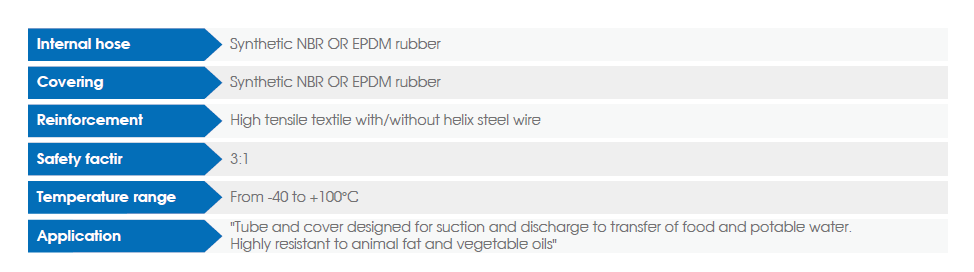

FDA GRADE SUCTION & DISCHARGE HOSE Construction:

Tube: White, smooth, NR, NBR or EPDM food quality rubber

Reinforcement: High strength synthetic fabric.

Cover: smooth(wrapped finish), synthetic rubber, blue or white, weathering resistant.

FDA GRADE SUCTION & DISCHARGE HOSE Application:

FDA approved food hose designed for the delivery of foods such as milk, Juice, beer, edible oil, daily products etc.

Recommended for the food transfer application that demands both flexibility and ruggedness with a clean white FDA grade tube.

The food grade nitrile tube is odorless and tasteless for those oily transfer applications. Excellent for discharge applications.

This ultra smooth microbe resistant tube is built on special stainless steel mandrels for cleanliness.

FDA GRADE SUCTION & DISCHARGE HOSE Temperature:

-32℃ to 80℃(-90℉ to +176℉)

FDA GRADE SUCTION & DISCHARGE HOSE Characteristic:

FDA grade tube

Weather and abrasion resistant cover

Handling wide variety of food products

Specification:

| PART NUMBER | HOSE SIZES | OD | OPERATING PRESSURE | BURST PRESSURE | BEND RASIUS | WEIGHT | LENGTH PER PCS | |||||||

| ID | DN | MN | INCH | MM | BAR | PSI | BAR | PSI | MM | KGS/M | METER | |||

| SPI-19 | -12 | 19.00 | 3/4” | 31.00 | 10 | 150 | 30 | 450 | 150 | 0.67 | 20/40/60 | |||

| SPI-25 | -16 | 25.40 | 1” | 37.00 | 10 | 150 | 30 | 450 | 200 | .084 | 20/40/60 | |||

| SPI-32 | -20 | 31.80 | 1 1/4” | 45.00 | 10 | 150 | 30 | 450 | 250 | 1.20 | 20/40/60 | |||

| SPI-38 | -24 | 38.10 | 1 1/2” | 52.00 | 10 | 150 | 30 | 450 | 300 | 1.52 | 20/40/60 | |||

| SPI-50 | -32 | 51.00 | 2” | 65.00 | 10 | 150 | 30 | 450 | 350 | 1.96 | 20/40/60 | |||

| SPI-65 | -40 | 63.50 | 2 1/2” | 80.00 | 10 | 150 | 30 | 450 | 400 | 2.95 | 20/40/60 | |||

| SPI-76 | -48 | 76.20 | 3” | 92.00 | 10 | 150 | 30 | 450 | 450 | 3.44 | 20/40/60 | |||

| SPI-100 | -64 | 102.00 | 4” | 120.00 | 10 | 150 | 30 | 450 | 500 | 5.06 | 20/40/60 | |||

Delivery

HYRUBBERS built excellent transportation newt work. The rubber hose could be delivered to clients by sea, by air, by highway transportation, to make sure the clients get the rubber hose in time.